As a result despite of these experimental studies aiming to study the compression failure mechanisms of cross ply laminates direct experimental evidences on the failure initiation and evolution processes are still needed to.

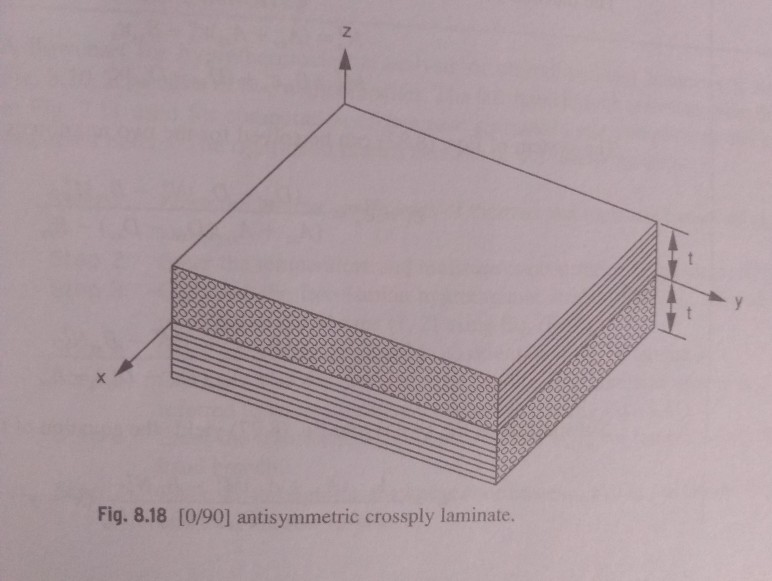

Carbon epoxy crossply laminates.

Properties carbon epoxy composite tube.

Thermal expansion coefficient longitudinal.

A small sample of aerospace grade carbon fibre epoxy laminate in materials science a composite laminate is an assembly of layers of fibrous composite materials which can be joined to provide required engineering properties including in plane stiffness bending stiffness strength and coefficient of thermal expansion.

The study of these two laminates allows to compare the evolution of transverse cracks in mode i for different ply thicknesses and types embedded and outer plies in both loading scenarios.

The aim is to unfold the damage accumulation process understand the interaction between different damage mechanisms and quantify their contribution to stiffness degradation.

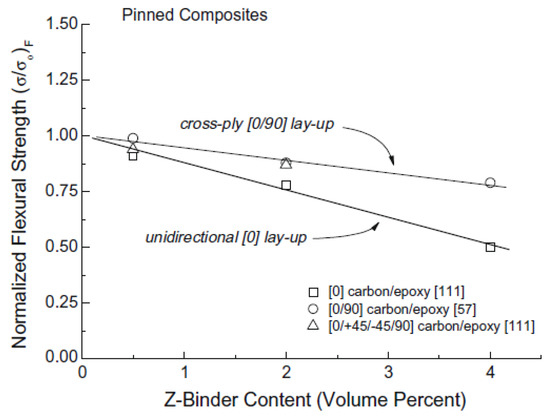

Pressive failure of the cross ply laminates using t800 924c carbon epoxy the results demonstrated that with fractographic methods it is prohibitively di ffi cult to evaluate the ply.

From the mechanical properties of the composite listed in table 16 2 and the shear lag model the axial modulus of as4 3501 6 carbon epoxy cross ply laminate 0 90 2 s was calculated as a function of matrix crack density from equation 16 24 and compared with the experimental data as well as the results without the effects of residual thermal stresses in fig.

Volume fraction of fibres 55 60.

16 19 it can be seen that the prediction underestimates the stiffness reduction at high fatigue cycles.

Three kinds of cnt epoxy laminates 0 90 s 60 0 60 s 0 45 90 45 s were successfully fabricated using aligned cnt epoxy prepreg sheets.

The process of matrix cracking has been analysed for two different carbon epoxy cross ply laminates under static and fatigue loading.

The normalized stiffness of the cf peek 0 2 90 2 2s cross ply laminate subjected to fatigue stresses of 60 or 70 of the static strength was calculated as a function of the normalized fatigue cycle with the stress redistribution function defined in terms of the shear lag analysis compared with the corresponding experimental data in fig.

In part i of this study quasi static and impact bending properties of four aeronautical grade carbon epoxy laminates have been determined and compared.

Compressive strength longitudinal.

Materials tested were unidirectional cross ply tape and bidirectional woven textile fabric carbon fiber lay up architectures impregnated with standard and rubber.

Properties carbon epoxy composite rod.

Soutis examined the compressive failure of the cross ply laminates using t800 924c carbon epoxy the results demonstrated that with fractographic methods it is prohibitively difficult to evaluate the ply interactions because of the extensive post failure damage.