Bend relief is provided at the end of bending edge in sheet metal design to avoid any crack tearing in the corner.

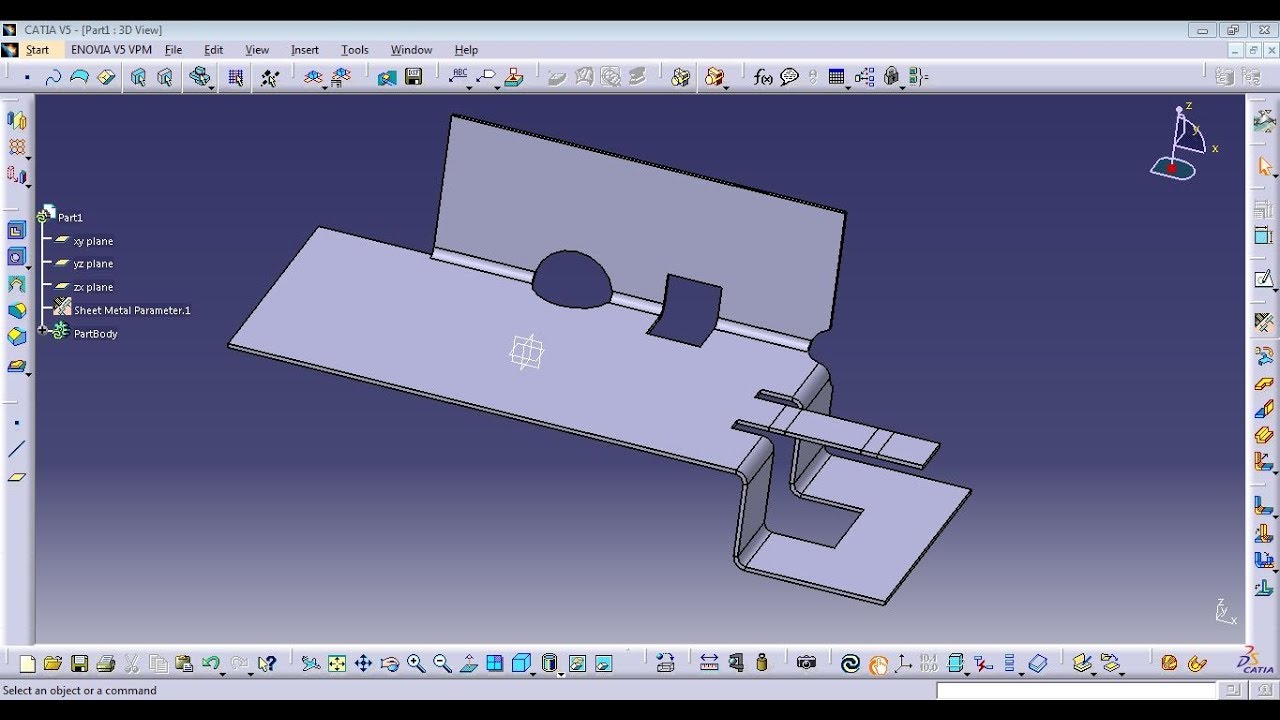

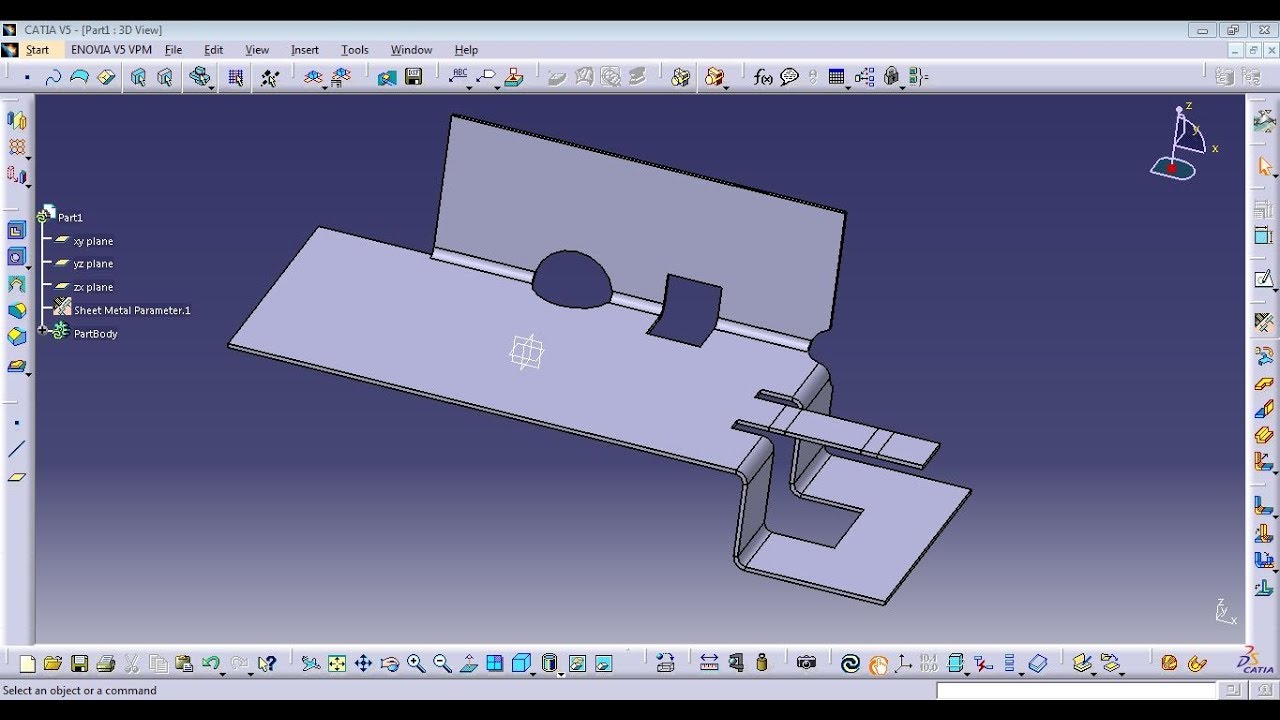

Corner relief in sheet metal catia.

Scope is the selection of the sheetmetal option.

Extrude hole size position guidelines creating an extruded hole using a punching process requires extreme pressure force.

Click sheet metal parameters.

Select collect all corners will populate all corners that fall into corner selection.

Click corner relief.

Within the tools options general parameters knowledge tab check the load extended language libraries option.

By default the circular profile is active.

This section explains how to change the bend corner relief.

Relief height is generally kept greater than two times of sheet thickness plus bend radius.

Select the supports on which a corner relief should be created here we chose surfacic flange 1 and surfacic flange 2 a notch was defined on the.

Support 1 2 3 specifies the supports for the corner relief centers defines the center location for a circular profile radius defines the radius for a circular profile.

Define corner will auto populate faces that define the corner.

As per sheet metal design thumb rules the depth of bend relief should be greater than or equal to the inside bend radius of the bend and the width of the bend relief should be the same as the sheet metal thickness or more.

Catia sheet metal design catia v5r19 creating sheet metal parts page 78 wichita state university type specifies whether corner relief will be circular square or a user profile.

Open cornerrelief01 catpart if you are using the sheet metal design workbench.

Would just like to add few extra points the use of corner relief is to avoid tear.

Creating a local corner relief.

1 the side edges can be cutoff and then a bend can be made along the longer sheet edge.